The Mystery of the Toyota Production System Unveiled

What’s the real power of the Toyota Production System. As most of us now know, it was never about the tools and solutions Toyota readily shared. It is not about the Japanese culture and/or worker discipline. We are closer to understanding the mystery when we say it is about the unseen Toyota management system, but even that is just the mechanism used to employ the secret.

Taiichi Ohno, considered the father of the Toyota Production system stated,

“The Toyota style is not to create results by working hard. It is a system that says there is no limit to people’s creativity. People don’t go to Toyota to ‘work’ they go there to think.”

The real secret, is to continually challenge the organization to solve problems, to think, to create, to innovate our way through specific, clearly communicated challenges. Because, there is no limit to people’s creativity. That is the secret. Human creativity applied to designing, solving, and achieving excellence.

No Problem is A Problem

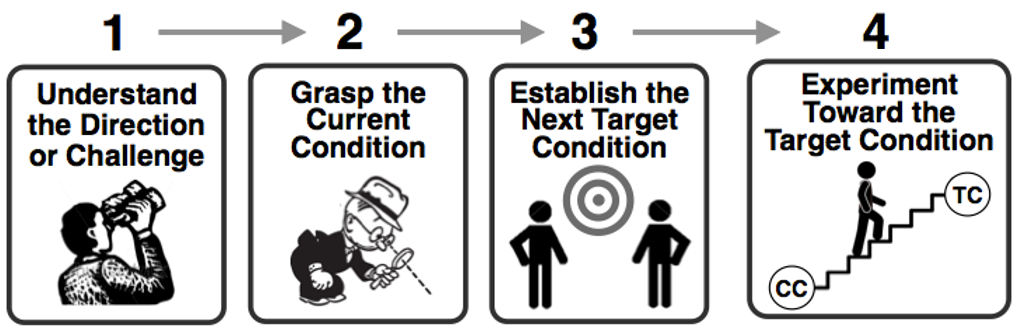

The frequently told story of a Toyota management coach telling a General Motors NUMMI plant manager that “no problem, is a problem” sums the secret up perfectly. Without problems to solve people’s energy and creativity goes unused, it sits idled. Great leaders create gaps for their people, then coach them through improvement and learning cycles. Leading in this fashion aligns people to solve the organization’s big problems. The resulting improvements in Safety, Quality, Delivery, Cost, Engagement, and Environment are what we call “Creative Benefit.”

C2V = Challenged, Creative, Valued.

Creating a “Thriving Environment” allows leaders to more effectively challenge people to think, achieve, and grow. More importantly, leaders can now focus the human need to achieve, on business goals and objectives by generating challenges, creating gaps, and exposing problems needing creativity to solve. The value of the organization rises as the value of the individuals rise. We describe this approach as C2V. It means: Challenged, Creative, Valued. This is a pattern for real business improvement, personal growth, and achievement. It is a key to successful leadership and to helping others achieve and excel in their work and lives.

Create a Thriving Environment

Abraham Maslow the famed American psychologist helped to describe and prioritize human needs, (Maslow’s Hierarchy of Needs referenced below). The needs build on each other and once one level of human need is met, we strive for more, the next level. So, once we are fed, clothed, and safely sheltered we start to seek relationships, respect, and finally achievement and growth. Leaders must create environments where people thrive, where basic needs are met so higher needs can be explored.

Abraham Maslow’s Hierarchy of Needs

- Physiological needs

- Safety needs –

- Love and belongingness needs

- Esteem needs

- Self-actualization needs

From: Maslow’s Hierarchy of Needs | Simply Psychology

https://www.simplypsychology.org/maslow.html

People-Centric Leadership.

As we consider Taiichi Ohno’s statement and better understand human needs, the mystery of gaining excellent business results through continuous improvement is clear. All improvements are centered around human activities in life. We continue to experiment, learn, and achieve because of our human nature. Business leaders able to understand this axiom and successfully apply it to organizational design and leadership are much more successful than leaders who cannot.

Creative Benefit

Let me introduce you to a new term: “Creative Benefit.”

Creative Benefit is the result of your organization’s combined creative force focused on achieving your target, vision, mission, and goals. It comes from communicating and aligning organizational challenges in measurable ways. Then, encouraging the natural creative process that occurs within the human mind. Creative Benefit is the sum of all the creativity you hold in your organization put to work solving your business problems.

Executive Role; Maximize Shareholder Value or Creative Benefit?

If like me, you believe all business achievement and improvement comes from our people, then you may want to consider your role in the organization differently. We are told our role as executives is to maximize shareholder value. What if instead, your role is to maximize the creative benefit in your organization? What would that look like? How would you lead differently? How can we measure creative benefit?

Allow me to share a leadership approach where you get crystal clear on what you are trying to achieve and work to maximize creative benefit. Then, I’ll share a few simple ways to engage and align your organization to get it done.

Engaging and Aligning the Organization

Is your organization clear on what you, its leader, are trying to achieve?

As executives we craft words into Vision Statements, keeping them short as possible; easy to remember, hopefully, easy for people to identify with.

We put similar words to annual company goals & objectives. We repeat this approach with our mission, values, and principles.

But, is the message heard and received by our people the same as the message we sent?

Do they fully understand what we need or expect them to achieve based on just our words?

Organization Visual Design Graphics (VDG)

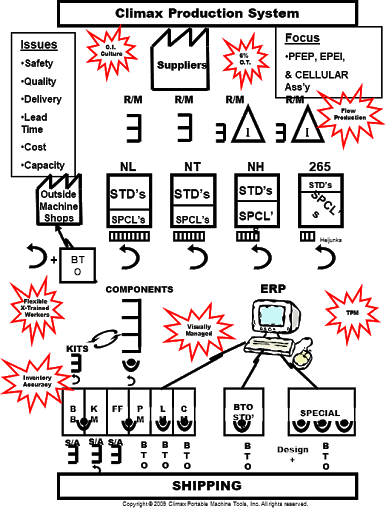

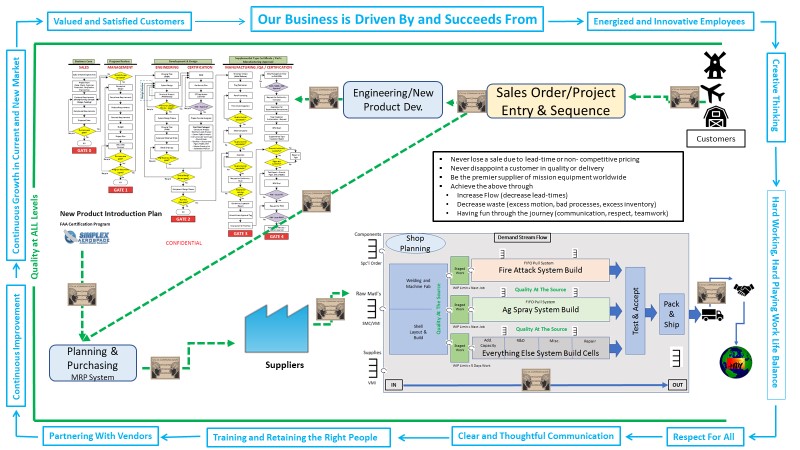

Here are a few examples of organizational visions shown in a graphic format. They are storyboards, allowing leaders an opportunity to tell the story of how she sees the future business operating pattern; the Target. They are built collaboratively with stakeholders, leaders, and staff so they are shared broadly and understood by all. The graphic works in conjunction with business vision and mission statements.

It is a thinking, design, strategy, and communication tool. It is dynamic and the center of all business conversations. It is an inclusive and transparent approach to engaging the creativity, innovation, and energy of your organization.

Climax Portable Machining and Welding Systems Vision Statement:

We envision a world where all people who do maintenance, repair, or manufacturing work optimize their performance, efficiency, and safety by using the optimal combination of portable machining, welding, and testing systems.

Vision Statement

Uncompromising safety and quality through innovation, diversify and expand our product offerings, enhanced brand recognition.

Envision an Organization in the Future

These graphics were designed with a desired future state in mind, customer demand, lead time, quality management system, and flow are new expectations of the envisioned pattern. The intent is to stretch the organization causing meaningful and aligned changes to provide higher quality, lower cost, shorter lead time products and services to customers. The design drives improvement in flow, elimination of waste, and team member engagement. Real and radical change needed to compete, thrive, and sustain.

It is not a status-quo incremental approach to improving business performance. Instead, it is a breakthrough approach with a clean piece of paper. We ask, if we could do this work any way we wanted, knowing what we know today, how would we organize and run the business?

Continuous Improvement or, Business Improvement

In 1990 a book titled, “The Machine That Changed The World” was written by several MIT researchers. Many of us, have since taken the learning from their study and attempted to imitate the system design and tools they discovered. Unfortunately, imitating the success the Toyota Motor Company enjoyed has turned into a frustrating endeavor with many more failing than succeeding. A primary cause of American companies failing to match Toyota’s success is a failure of leadership involvement and adoption.

I believe if in the book, Womack and Jones had stated they observed a Lean business system instead of a Lean production system, successful transformations would have out-numbered failures. By using the term lean production system many executives tapped their operations and manufacturing leaders and said go check it out. If it had said, lean business systems, those same executives may have checked it out themselves and become the business leaders to revolutionize American business.

Work on the Right Things.

This is not your typical Lean Transformation work where we 5S everything, then do a massive setup reduction project, introduce six sigma, and run kaizen after kaizen in the factory. This is an approach where we ask what must be done to achieve the vision? Who must be involved to complete that work? There are lots of things a business can work on but what needs to be worked on to accomplish the design? Everything else is a form of waste. Even if it sounds good.

Current Improvement Approaches are Failing.

In my research I have found only three percent of the companies attempting a Lean transformation realize the benefits they hoped to gain. To answer the question why, we only need look at executive leaders in those companies. They generally assign the work to other lower level leaders, typically operation leaders. Clear expectations of impact on financial performance is missing. Recognizing how much creativity is sitting idled on the sideline is absent. And learning, teaching, and coaching their teams through business tools and approaches is absent.

Target? Actual? Please Explain.

What is the top business Target? (hear business vision).

How are we measuring & communicating Actual performance to plan?

Finally, how do we identify & learn of the gaps between Target and Actual? Have we focused the organization on closing the gaps and moving the business forward.?

Summary

In summary, leaders start by creating a clear vision, preferably graphically. Work in collaboration with stakeholders to gain consensus and communicate the vision. Align their organizations through cascading challenges aimed at enrolling team members while maximizing creative benefit. They begin this work by creating a thriving work environment and culture where their people are ready to learn, grow, and achieve at the top of their game. Finally, they are personally engaged and involved in this work. Because it is not just about operational excellence, it is about business system performance and excellence.